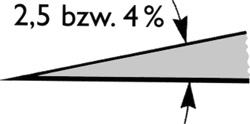

“Subgrade” means the compacted soils at the bottom, which has to be made prior to the placement of the new base material. It is important to spend as much time as possible compacting to achieve an even, load-bearing compaction, which fulfills the requirements of the base course. For construction reasons, the longitudinal and transverse slope required on the stone surface must be built on all layer surfaces, including the subgrade. Minimum cross slope: 2.5 %, for water-sensitive floors 4 %.

Sluicing grained aggregates as final completing of the joints improves the resilience of the joint filling and provides the paving surface with good stability from the start. The joints need maintenance. For this purpose, an extra sand back filling is necessary, especially in the beginning, until the joint remains completely closed.

Make the bedding of regular thickness and of the correct height and profile. The thickness after compacting should be 3 to 5 cm. In general, surfaces for traffic load require graded bedding materials with grains of at least 4 mm. Suitable materials for private, pedestrian traffics are materials with all-zero grains of 0/4, 0/5, 0/8 or 0/11 mm. The bedding mortar must be filter-stable to the base material! The use of limestone can lead to increased efflorescence. ** The bedding material should be evenly mixed and enenly soaked and quickly laid in place. After screeding, it´s not allowed to walk-on or drive on the surface.

Always compare the delivery note with the order. Compare the size, color, surface texture and quantity of concrete pavers or slabs. Compare supplied goods with the previously agreed samples. Clarify any discrepancies with the partner or supplier providing the goods before laying the stones.

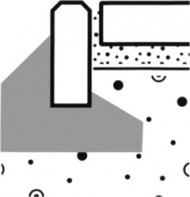

Paving surfaces require edge restraints. Define the positioning of the edging by laying individual rows of stones before laying the pavers themselves and consider the agreed width of the paving surface. The elements used for edging, e.g. curbstones or edging stones, should be laid at the right height and aligned on a concrete base. They should also have a concrete support at the rear. The foundation and the rear support are to be build using freshly made cement.

Water that accrues superficial must be deviate quickly by the shortest flow-path from the surface. Gutters need to have a longitudinal slope of at least 0,5 %. Lay the components, e.g. gutter stones, gutter plates or paving stones, at the correct height and aligned on a concrete base. Fill joints with suitable bonded mortar. Drainage gutters need to be laid with expansion joints.

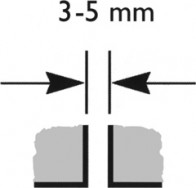

Lay concrete pavers and concrete slabs in the agreed pattern with 3-5 mm joint. Spacers between the stones do not specify the joint width. Never lay pavers without joints against each. For slabs, we recommend using standard plastic spacers.

The axes of the joints have to be in uniform course. Sufficient string lines in lengthwise and crosswise direction ensure linear joints. We recommend selecting pavers simultaneously from more than one bundle to mix the color efficiently over the entire surface. When laying paving stones with sharp edges (mainly large-sized stones), we recommend using the METTEN edge protection profile in order to prevent cracking at the edges. Infill pavers must not be smaller than the half of the full-sized paver is. The cutted stones should not be acute-angled. We recommend using a wet-cut table saw.

Fill in joints with suitable, washed and non-dying jointing material. Sweep or sluice the jointing material continuously while proceeding the laying. Prefer a graded joint material with a grain size of at least 2 mm. It needs to be filter stable to the bedding material. Fill the joints completely with joint material. Do not leave any residue on the surface.

If alternatively a rigid filler is used (e.g. jointing mortar etc.), please take notice of the manufacturer’s instructions. Always lay a sample area to check if the material is suitable. Always consider a sufficient number of expansion joints. Despite careful planning and laying of the surface, bonded or composite construction (bonded joint with unbound bedding and/or bearing layer according to "ZTV Wegebau") can lead to tension cracks in the joint and in the concrete products.

Do not vibrate slabs – just tap them with a rubber hammer.

Before vibrating, sweep off paving stones completely in order to remove surplus joint material. Vibrate colored pavers and pavers with a special surface design only when the surface is dry and a sliding slab device is used. Do not vibrate pavement without joint sealing. Vibrate watered pavement only after bedding and subbase have dried sufficiently.

They have to be load bearing, stable to deformation and sufficiently permeable to water. Usually base layers are made by using unbonded aggregates (base courses without binding, ToB). Base layers must be procuced of sufficient thickness, in the correct profile, even and load-bearing. The required slope depends on the slope of the paver surface (minimum crosswise slope: 2,5 %). A frost protection layer is also a base layer without binding.

*Please note the special processing instructions when laying Belpasso or Senzo paving.

**When using bedding and jointing materials with a capillary effect or materials which tend to grinding (e.g. limestone chippings), the surface may be discolored due to adhering flour or increased salting out due to increased water transportation (carbonate efflorescence). These deposits can have a massive and recurring effect on the color.

These rules are based significantly on experience and are largely state-of-the-art. There is no liability accepted for damage resulting from the application of these rules. The complete information is contained in the German brochure „Richtig Planen und Ausführen – Dauerhafte Verkehrsflächen mit Betonpflastersteinen” of Bundesverband Deutsche Beton- und Fertigteilindustrie e.V., SLG Betonverband Straße, Landschaft, Garten e.V., Postfach 210267, 53157 Bonn.

Please note the following specificitiesm for laying paving stones on a cast concrete surface, e.g. balcony or terrace:

Make the cast concrete surface with smooth abrasion and a 2 % slope. If the cast concrete slab is already in place and does not have a slope, apply a sloping unbonded screed with a 2 % slope. The thickness of the screed should be at least 2 cm at the thinnest point.

If there is a usable space under the cast concrete surface, for example a cellar, apply a seal in accordance with DIN 18195 / DIN 18336 with directed water drainage over the sloping unbonding screed.

In any case, make sure that the slope of your cast concrete surface is sufficient to avoid standing water on the surface. There must be no accumulation of moisture under the laid paving, as this can lead to discoloration, dark edges and possibly to protracted efflorescence.

But even if the slab does not come into direct contact with water, for example when laying on pedestals, there must be no water under the slabs. Reason: If the sun heats the laid slabs, the water would accumulate underneath the slab (condensation). This condensed water rises through the capillaries of the slab and transports notably the unsaturated lime particles in the slab on its surface. Result: stubborn lime efflorescence.

In addition to the slope of the cast concrete surface, create a directed water drainage at the edge of the paving area. Depending on the nature of the soil and the situation, this can consist of a course of gravel, a drainage channel, a rain gutter, etc. This measure also serves to avoid a build-up of moisture.

After checking the supplied paving stones, they can either be laid on

Laying on pedestals or small mortar bags:

Slabs with size 60x30 should be supported in center (see drawing 2).

The best method is laying on water-bearing drainage courses (for example Gutjahr Aquadrain T+). This type of installation is the best way to reduce the risk of moisture build-up. It also enables the joint to be filled, for example with NEROS joint chippings.